Aluminum Foundry topics presented in a clear format

Wiki Article

A Deep Study Steel Foundries: Necessary Information and Sector Patterns

Metal factories play a necessary function in the production sector, transforming basic materials into crucial elements. The procedures involved, from thawing to quality control, are complex and require accuracy. Current developments are improving the industry, presenting automation and sustainability techniques. Yet, challenges persist, specifically concerning labor and material costs. Recognizing these components is fundamental for grasping the current landscape and future instructions of factories. What lies ahead for this foundational market?Understanding the Steel Foundry Refine

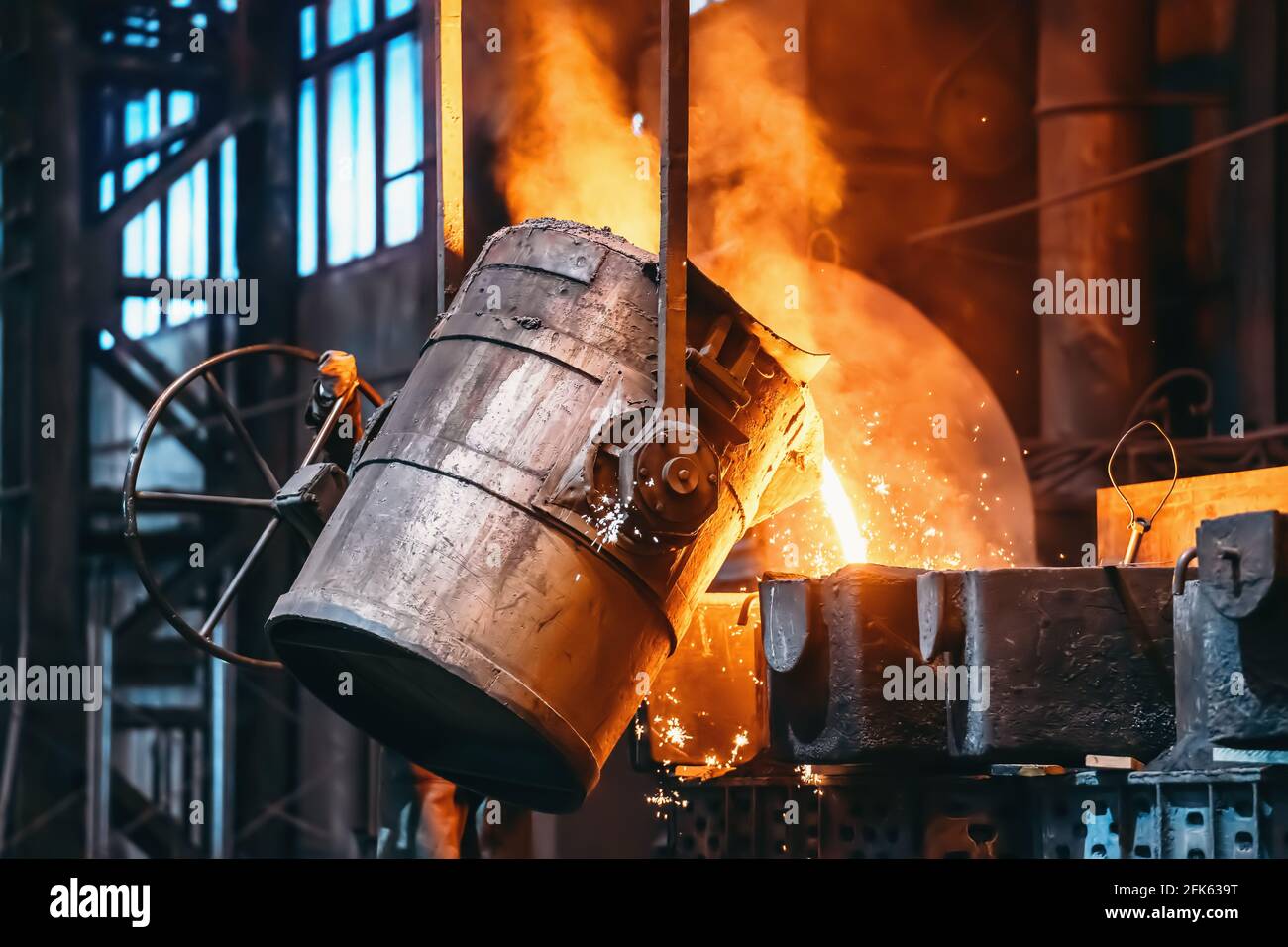

Although the metal foundry process may appear complicated, it revolves around a few essential stages that transform resources into ended up steel items. At first, basic materials such as steel ores, scrap metal, and alloys are sourced. These materials undertake melting in heaters, getting to heats to dissolve the metal. Once molten, the metal is put into mold and mildews, where it cools down and strengthens right into the wanted formComplying with solidification, the spreadings are eliminated from the mold and mildews, resulting in further handling. This may include trimming excess product, surface area completing, and heat treatment to improve properties. Quality assurance inspections are essential throughout the procedure to guarantee that the end products fulfill called for standards and specifications.

Key Technologies Fueling Shop Advancements

The advancements in modern technology have actually substantially influenced the metal shop market, driving developments that improve performance and product high quality. Trick modern technologies reshaping this industry include automation and robotics, which streamline procedures and lower labor prices, permitting for precision in mold making and steel putting. Additionally, the fostering of 3D printing is reinventing pattern production, allowing intricate styles that typical methods can not accomplish. Moreover, simulation software has become a necessary tool, allowing factories to predict and fix prospective casting defects prior to production, consequently conserving time and resources. The integration of IoT (Internet of Things) gadgets improves tracking and information collection, promoting real-time modifications to procedures. Improvements in metallurgy, such as the advancement of new alloys, are increasing the capacities of shops to generate more powerful and lighter elements. Together, these innovations are transforming the landscape of steel shops, driving them toward better advancement and competitiveness.The Function of Top Quality Control in Metal Casting

Quality control plays an essential duty in metal spreading, guaranteeing that each component satisfies stringent requirements and performance standards. This process entails a selection of methods, consisting of aesthetic inspections, dimensional measurements, and material screening - Aluminum Foundry. Shops utilize quality control personnel that keep track of each phase of production, from basic material selection to the final product examinationBy utilizing advanced modern technologies such as non-destructive screening and automatic examination systems, metal foundries can identify defects early in the production cycle. This aggressive approach reduces waste and decreases the possibility of expensive rework. In addition, adherence to sector criteria, such as ISO qualifications, enhances a foundry's commitment to top quality, improving consumer self-confidence and contentment.

Inevitably, reliable quality assurance not just enhances the reliability and sturdiness of cast parts but likewise drives constant renovation within the shop, promoting a society of quality and advancement in steel spreading procedures.

Sustainability and Environmental Practices in Foundries

As metal factories increasingly acknowledge their influence on the setting, a dedication to sustainability has actually become vital in their operational methods (Aluminum Foundry). Numerous foundries are carrying out energy-efficient modern technologies, such as electric induction heating systems, which considerably lower greenhouse gas discharges contrasted to standard approaches. The fostering of recycled products, especially scrap metal, has likewise acquired traction, reducing waste and preserving natural depositsFurthermore, official statement water monitoring practices are being improved to decrease consumption and prevent contamination. Many shops are purchasing closed-loop systems that recycle water made use of in cooling and cleansing procedures. Additionally, dirt and exhausts control modern technologies are being updated to ensure compliance with environmental policies.

Future Patterns and Difficulties in the Steel Shop Sector

Emerging fads in the steel factory industry highlight a shift towards advanced technologies and innovative techniques targeted at enhancing efficiency and competition. Automation, including robotics and fabricated intelligence, is increasingly taken on to improve operations and reduce labor costs. Furthermore, the combination of Sector 4.0 modern technologies assists in real-time data analysis, allowing better decision-making and anticipating maintenance.Difficulties linger. The sector faces a competent labor lack, demanding financial investment in workforce training and growth. Rising and fall raw material costs and supply chain interruptions present significant obstacles. Ecological policies are ending up being stricter, pushing foundries to adopt lasting practices that can be pricey at first but useful long-lasting.

Additionally, the demand for lightweight and high-performance alloys is climbing, calling for foundries to innovate their materials and procedures. Stabilizing these patterns with ongoing challenges will be essential for the future success of the steel shop sector.

Often Asked Concerns

What Is the History of Metal Foundries?

Just How Do Foundries Determine Steel Alloy Compositions?

Foundries determine steel alloy make-ups with a mix of empirical testing, computer modeling, and industry standards. They analyze preferred buildings, application needs, and cost-effectiveness, making certain the last alloy satisfies details efficiency standards for intended usages.What Are one of the most Typical Foundry Materials Utilized?

The most usual foundry products consist of cast iron, light weight aluminum, steel, brass, and bronze. These materials are preferred for their longevity, versatility, and stamina, making them suitable for various applications in production and building.Just How Do Factories Handle Hazardous Waste Disposal?

Shops manage dangerous waste disposal through rigorous adherence to ecological regulations, using specialized containment systems, reusing campaigns, and collaborations with qualified waste management companies to guarantee secure and compliant disposal of toxic materials.What Occupation Opportunities Exist in the Steel Foundry Sector?

Steel foundries play a vital role in the production field, transforming raw materials right into important parts. The metal shop procedure may seem complicated, it revolves around a few fundamental phases that transform raw products right into completed metal products. The developments in technology have actually substantially impacted the metal factory industry, driving click resources advancements that enhance performance and product top quality. The history of steel shops dates back to ancient human beings, where artisans first melted metals to develop designs and tools. The steel shop industry provides diverse occupation opportunities, including duties in design, quality control, procedures management, and environmental compliance.

Report this wiki page